E-mail : pawan.agarwal@gbes.in

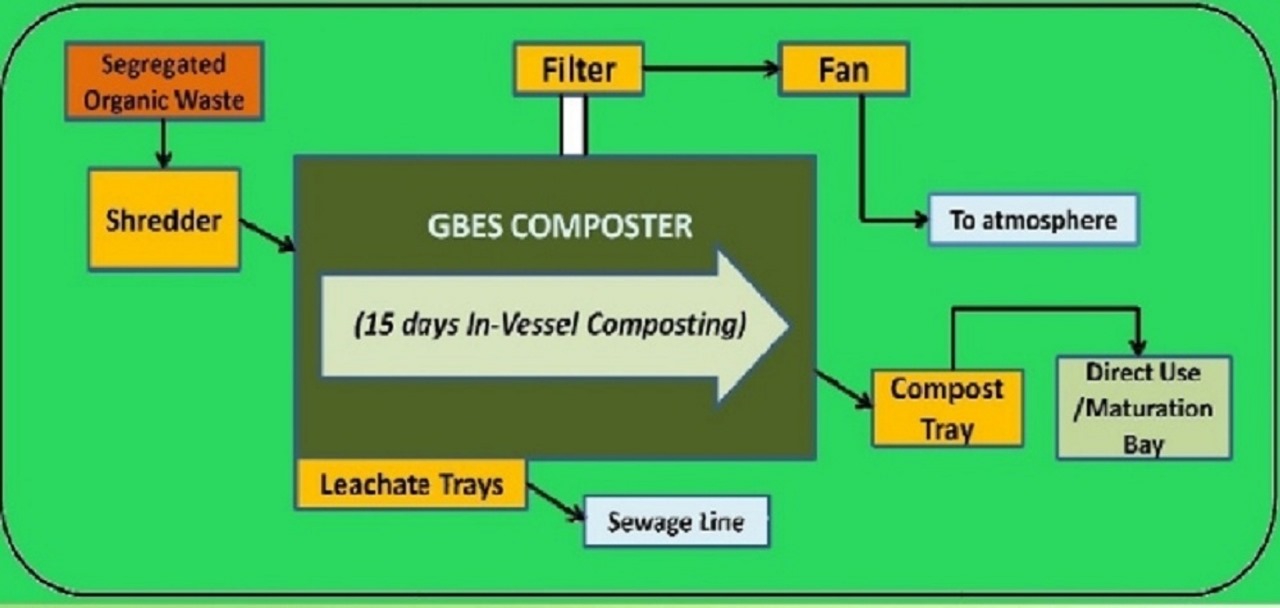

GBES Composters are fully automatic Bio-Mechanical Composters. These canconvert organic waste into nitrogen rich compost by reducing its volume by 65-80% of the original.The Composter is Specially Designed for Hotels, Restaurants and Large Canteens to Convert Kitchen waste into highly nutritious soil Manure. Highly Energy efficient and works on Natural Composting Technique. They are easy to install and require minimum maintenance.A skilled labour is required during the installation of the machine.